Enhance the metal spray coating protective system in iron & steel structure with sealant application and spray painting. The sealant penetrates into the surface material thus filling the gaps and pores reducing the total area of exposed metal and the rate of dissolution.

The application of sealants on the metal smoothens the surface texture and prevents the retention of grime and other impurities or contaminants to reduce the rate of surface attack. Specialised sealant application process at Mythri offers multi benefit of sealing, smoothing and durability of the coating appearance through spray painting.

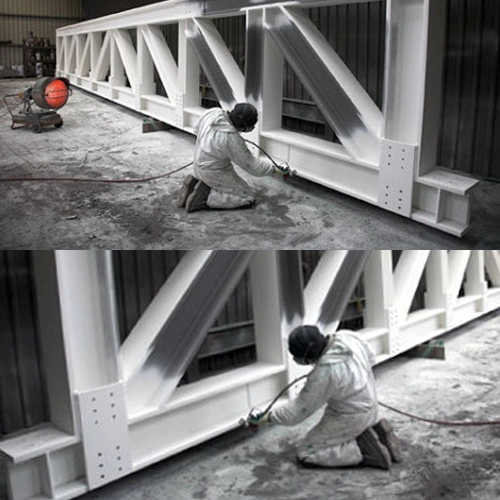

Mythri has versatile experience in Airless Spray Painting. Our technique includes a spraying device to apply the coating through a compressed air system onto the surface material.

The process is applied to an object using an air-pressurised spray gun with nozzle, air compressor and a basin to store paint. The mechanism of air spray painting is triggered when the paint mixes with a compressed air stream and released into a fine spray output.

Penetration

The coating offers superior coverage into pits and crevices.

Uniformity

The coating output is uniform and thick supporting economical layering.

Adhesion

The process adopts wet coating to facilitate better adhesive properties.

Increased Speed

Airless sprays are faster and suitable for a short weather window in comparison, benefiting less time and less labor cost.

Enhanced Quality

Airless spray paint produces an even coat of paint/mil build on any type of surface with a high quality finish.

Highly Versatile

Airless spraying technique is suitable for a wide range of coatings with high mobility covering both interior and exterior jobs sites.

Mythri supports maximisation of timely deliverables to real-time schemas with well planned and executed solutions without conventional lags.